900N multifunctional Box Assembly machine is a model developed and manufactured to fully automate the book style and shoulder &neck rigid box assembly process. It can work with most types of the book style rigid boxes on the market, and it solves problems of the process being too complicated, taking too much time and consuming too much labor. It sprays glue and then places the base box onto the rigid covers accurately and efficiently. This machine drastically increases the precision and working speed for the box manufacturers, highly recommended for book style rigid box projects. Furthermore, this machine can be upgraded to make many other box products, including: Collapsible rigid boxes, cosmetic powder boxes.

Main features:

1. High safety, short setting and adjusting time, fully digital, manual debugging is not needed, which is convenient and fast.

2. Easy to operate, anyone can easily learn to use it well.

3. Fast processing speed, spraying in lines, which is glue saving, strong bonding. No leakage.

4. Automatic glue dispensing, diversified and simplified.

5. The bubble pressing process after the box glued to the rigid cover is precise and stable.

6. The servo motor and automatic control system used in each part are imported high-end accessories with high stability, high accuracy and long service life.

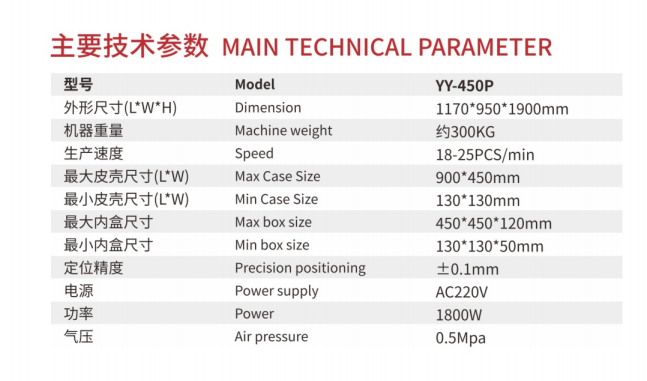

Main Specs:

1. Japanese Panasonic PLC, frequency converter, temperature controller.

2. Japanese Panasonic photoelectric sensor.

3. Japanese Panasonic servo motor.

4. Japanese Panasonic servo drive.

4. Japanese Panasonic negative pressure switch.

5. Schneider Electric SA proximity switch sensor.

6. XWB DC motor.

7. Taiwan Meanwell power.

8. Jingtai hot melt glue box.

9. Pneumatic vacuum electronic components-Taiwan AIRTAC, XINGCHEN, AIRBEST.

Delivery time and payment:

7-10 days after receiving a 30% deposit. The balance needs to be paid before shipment.

Limited Warranty :

One year.

Installation and debugging:

ZJH will send technicians to do installation and provide training if the situation allows. The travel expenses of the technicians including transportation and accommodation costs is to be borne by the buyer.