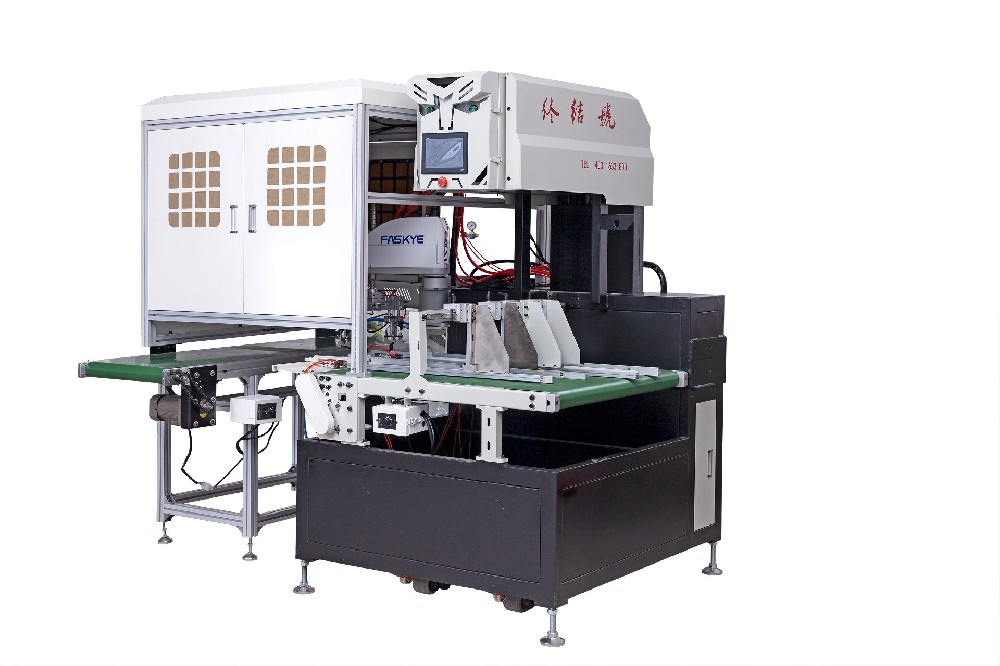

1. Multiple functions: This positioning system can work both rigid box positioning, rigid cover positioning.

2. Short adjusting time: The visual positioning system allows it to set up a job very quickly, usually less than 30 mins.

3. The robotic arm is strong and made of modules, easy to do maintenance and impossible to break, unlike the traditional robotic arms that are fragile and nearly impossible to repair.

4. Highly cost effective, can be added to any semi-automatic box making line that has a feeder gluing machine and a conveyor belt, very budget-friendly for any factory owner who is looking to upgrade their semi-automatic box/rigid cover production line to fully automatic line.